Lifting and tilting devices for standard trolleys

Lifting and tilting devices for standard trolleys

Lift and tilting device

Type HKV-HBW

Suitable for lifting and tilting 200 and 300 liter bins according to DIN 9797

- Solid industrial execution guarenteed long-life

- Various tilting heights and tilting versions available

- Stationary version or optional with chassis (up to a tipping height of 2300 mm)

- Payload maximum 350 kg

- Dead man's control

- Hygienic design control box incl. operating elements on lifting column at ergonomic height

- Optical chain tension indicator

- High pressure cleaning resistant, safety class IP 65

- Mechanical safety precautions: Special chain break protection

- The safety cages is required from a tilting height of 2500 mm

- Standard execution: chain nickel-plated (16B-1)

- Highline execution:

chain made oft stainless steel (NO relubrication of grease necessary + chemical resistant)

No product in the request list!

Please select the desired article on the gray field next to the article no. by clicking the mouse.

No product in the Quick inquiry list!

Please select the desired article on the gray field next to the article no. by clicking the mouse.

Special executions on request possible

Material

Nearly complete made of stainless steel 1.4301, microplasted stainless steel surface

Description

The execution of the lifting and tilting device is determined by the type and viscosity of the bulk material and, if necessary, extended by special chutes, hoppers, lift forks or lifting platforms. Thus, the tilting devices can be adapted for almost any application.

Attention:

When using a 300 litre lifting and loading trolley, the tipping height is reduced by 150 mm. The safety distance between the lifting and charging trolley (standard trolley) and the device to be charged (e.g. hopper or similar) when tilted is 120 mm (DIN EN ISO 13854).

Up to a tipping height of 2300 mm, the lifting and tilting device can provided with a chassis. In addition, a safety fence is recommended from a tilting height of 2300 mm. From a tilting height of 3200 mm, the lifting and tilting device must be additionally secured to the wall or ceiling by the customer.

Special drop safety

The fall arrester is made of stainless steel and consists of a 4 mm thick U-profile rail with rectangular fixing holes and a pressure spring activated 25 mm fork.

The fall protection comes into operation for breaking the chain, or if the chain sags. When that happens, the compression spring is released and the fork turns into the fixing holes and Brind the load to an immediate stop.

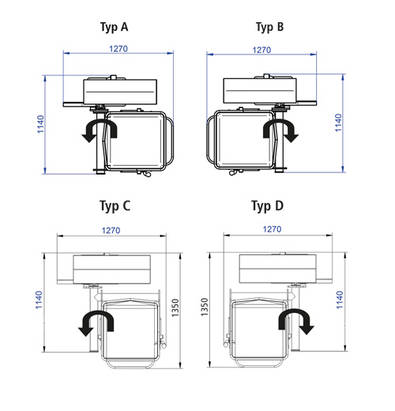

Executions of lifting and tilting devices

Distance between standard trolley and lifting column:

Version type A + B: approx. 130 mm

Version type C + D: approx. 230 mm

Technical Data

| Power supply | 3x 400 V; 50 Hz |

|---|---|

| Performance | 0,75 kW (gear motor) |

| Protection class | IP 65 |

| Loading capacity | 350 kg (incl. trolley) |

| Lifting speed | 5 m/min |

| Tilt angle | 120° |

| Adjustability | 2-stage adjustable in 150 mm each (device set to max. tipping height on delivery) |

Video

Anti crash device 1

End position detection by means of initiator + roller limit switch mounted at the top outside of the pillar.

Anti crash device 2

End position detection with the aid of initiator + roller limit switch integrated inside the pillar body.

Control elements

High-quality Schmersal control elements in hygienic design (IP69K) + Main switch with EMERGENCY STOP function (de-energised).

LIFTING AND TILTING DEVICE

LIFTING AND TILTING DEVICE