Sole-+ boot cleaning "Highline"

Sole-+ boot cleaning "Highline"

Sole-/ boot cleaning

Type Combiclean Highline

Compelled-guided cleaning and disinfection of soles + boots

- Robust and hygienic construction

- Hygienic design execution

- Siemens logo control, freely programmable

- Sensor-controlled brush roller rotation for round trip

via spring pot technology to save water, chemicals and energy costs - Boot cleaning module for cleaning the bootlegs

- Brush roller start of the boot module by means of a hand sensor

- Railing for a secure stand

- Brush rollers removable without tools

- High bristle quality with large field coverage

- LED status display for operating status and disinfectant level

- Adjustable brush roller running time and dosing quantity

- With side impact protection and splash guard

No product in the request list!

Please select the desired article on the gray field next to the article no. by clicking the mouse.

No product in the Quick inquiry list!

Please select the desired article on the gray field next to the article no. by clicking the mouse.

Delivery does not include optional accessories.

Material

Rustproof stainless steel 1.4301

Description

The Combiclean pass-through sole/boot cleaning machine was designed for optimal cleaning and disinfection of shoe soles with a high level of safety through hygienic forced guidance of personnel.

Two horizontal, rotating brush rollers with large-area bristles, covered with a stainless steel walking grid, guarantee thorough cleaning and disinfection of the soles with minimal time and energy expenditure. The brush rotation is activated automatically by a sensor as soon as the machine is entered. When the walking grate is crossed, the soles of the shoes are cleaned and disinfected at the same time by the bristles protruding above the grate.

A hand contact sensor in the retaining bar activates the cleaning of the boot shafts in a separate boot cleaning module with vertically rotating brush rollers.

The cleaning and disinfectant mixture is added automatically via an adjustable dosing system. The brushes can be removed without tools for cleaning the brush shafts. An integrated LED status display shows the operating status of the brushes and the disinfectant level: red = brushes not active, green = brushes active, flashing = disinfectant level low or empty.

Advantages

- Safe hygiene cycle thanks to forced guidance: defined sequence for cleaning and disinfecting soles and boots – particularly suitable for production areas where hygiene is critical.

- Thorough cleaning with minimal effort: two rotating brush rollers with large-area bristle coverage ensure reliable cleaning of soles and boots in a single pass.

- Resource-saving operation: sensor-controlled activation via spring pot technology – reduces water, chemical, and energy consumption.

- Constant dosing: cleaning and disinfectant mixture is automatically fed via an adjustable dosing system.

- Quick cleaning and maintenance: brush rollers can be removed without tools to clean the brush shafts.

- Greater transparency during operation (LED status display): the operating status of the brushes and the disinfectant level can be seen at a glance (red/green/flashing) – making it easier to check and manage refills.

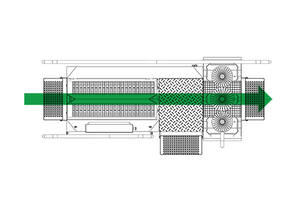

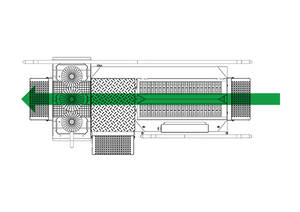

Passage direction

Left to right

Right to left

Technical Data

| Power supply | 3 x 400 V/N/PE; 50/ 60 Hz |

|---|---|

| Performance | 1,5 kW |

| Drain | 2" (DN 50) |

| Water connection | 3/4" AG, Mischwasser max. 43° C |

| Fusing | 16 A |